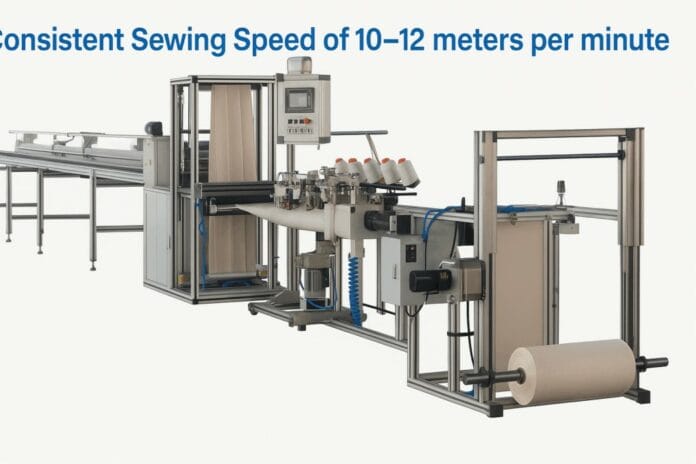

Overview of Automatic Filter Bag Sewing Machines

Automatic filter bag sewing machines are essential tools for manufacturers that produce filter bags. They streamline production by combining several functions and cutting down on labor.

Purpose and Functionality

These machines are designed to create filter bags for a bunch of different industries. You’ll find them in places dealing with dust collection, liquid filtration, or air purification.

Automating the sewing process ramps up both speed and accuracy. Many machines can crank out hundreds of bags per day—pretty impressive. They’re usually all-in-one, integrating sewing, cutting, and sometimes hot melting, which keeps things efficient and versatile for changing manufacturing needs.

Key Features

They’re packed with features to make life easier. Some highlights:

-

Automatic Feeding: Loads materials fast—less hassle for operators.

-

PLC Control System: Lets you manage the line without a headache.

-

Sewing Speed: Many models hit about 10 meters per minute.

-

Flexible Sizes: Handles bag diameters from roughly 120 mm up to 300 mm.

Control panels are usually pretty intuitive, so switching between sewing and hot welding is a breeze. That adaptability means you can keep up with shifting production demands.

Types of Filter Bags Supported

These machines aren’t picky—they work with a variety of filter bags, including:

-

Woven Fabric Bags: Popular in all sorts of industrial settings.

-

Non-Woven Fabric Bags: Great for air and liquid filtration jobs.

-

Fiberglass Felt Bags: Perfect when things get hot.

-

Meta-Aramid Bags: For the really tough environments.

Knowing what types of bags you need helps narrow down the right machine. Most models are flexible enough to handle a range of projects.

Core Components and Technologies

Inside every automatic filter bag sewing machine, a set of components work together to keep production humming. There’s the sewing mechanism, cutting and forming systems, and some pretty advanced control tech.

Sewing Mechanism

The sewing mechanism is basically the machine’s engine room. It’s usually got a high-speed sewing head—sometimes up to 2400 RPM—which means bags get stitched up fast.

Many machines use servo motors for better control and accuracy. That helps with smooth operation, especially when you’re switching between bag sizes (typically 120 mm to 300 mm in diameter).

Automatic thread cutting is a nice touch, too. It keeps things moving by trimming downtime between cycles.

Cutting and Forming Systems

Cutting and forming systems shape the bags. Integrated cutting tools slice fabrics to the right size, which is a big deal for consistency.

Cutting speeds are usually around 10 to 12 meters per minute. That’s quick enough to keep up with demand. A solid cutting mechanism can hit a tolerance of ±1.5 mm, so you’re not wasting material.

Some machines even use hot melting tech to seal edges better. This combo helps simplify the line and shortens the time spent on each bag.

Control and Automation

Control and automation systems are where things get smart. Most machines come with a PLC control system, making adjustments and operation way less complicated.

Modern panels let you jump between sewing and heat sealing functions without fuss. That keeps production flowing and cuts down on headaches.

Automatic monitoring can catch thread breaks or other hiccups before they become a big deal. That means fewer interruptions and more consistent quality.

Production Capabilities and Performance

Automatic filter bag sewing machines are built for speed and versatility. They boost production rates and handle a range of materials with surprising precision.

Sewing Speed and Efficiency

Speed is one of the big selling points here. Many machines hit 7 to 12 meters per minute. Some top-tier models can even reach 350 meters per hour for fabric.

If you’re aiming to produce 1,000 bags a day, these machines can make it happen. That kind of output can really transform a production line and help you stay competitive.

Handling of Different Materials

They’re not just fast—they’re adaptable. Whether you’re working with woven fiberglass or non-woven stuff, these machines take it in stride.

Being able to handle heavier fabrics means your filter bags come out tough and reliable. You can tweak settings for different materials, which is a lifesaver when switching between jobs.

Precision and Consistency

Stitching quality matters, especially for filter bags. Automatic machines use advanced tech to keep seams consistent and strong.

Some, like those with Juki sewing heads, can adjust stitching on the fly based on what you’re feeding in. That helps cut down on defects and keeps your products up to spec.

Material Compatibility and Application Areas

These machines can tackle a range of materials, which is crucial for keeping your operation flexible. Let’s look at some common options and the industries that rely on them.

Needle Punched Felt and Woven Fiberglass Processing

Needle punched felt and woven fiberglass are popular choices for filter bags. They’re both solid for air filtration work.

Needle punched felt is tough and lets air through, trapping dust pretty well. Woven fiberglass is lightweight but can take the heat and handle chemicals—handy for industrial settings.

Most automatic sewing machines can stitch these materials without a hitch. Consistent seams keep your filters working as they should.

Support for Specialized Fabrics

Some jobs call for specialty fabrics. PTFE-coated materials, for example, are a go-to when you need chemical resistance and durability.

These fabrics show up in harsh environments, like chemical plants. If your machine can handle them, that’s a big plus for flexibility.

Adjustable settings let you fine-tune things like speed and tension, which is key for getting the best results with different fabrics.

Industries Served

Automatic filter bag sewing machines find homes in all sorts of industries. A few big ones:

-

Air Filtration: Vital for HVAC systems—nobody wants dirty air indoors.

-

Food Processing: Filter bags help keep things clean and up to code.

-

Pharmaceuticals: Precision filtration is non-negotiable here. Machines help you hit strict standards.

-

Automotive: Used for air and oil filtration in vehicles—pretty important stuff.

With the right setup, you can pivot to different industries without too much trouble.

Advancements in Automation and Quality Control

Recent years have brought some cool upgrades to automatic filter bag sewing machines. You’ll see smarter controls, better detection systems, and more ways to customize.

Intelligent Centralized Control

Modern machines often feature centralized control systems. You can oversee multiple processes from one interface, which is honestly a huge time-saver.

-

User-Friendly Interface: Adjust settings on the fly—it’s pretty straightforward.

-

Data Integration: Machines track production stats, which is handy for troubleshooting or planning.

-

Remote Access: Some models let you tweak things from afar—pretty convenient.

Thread Break and Abnormality Detection

Thread break and abnormality detection systems are a real game changer. They keep tabs on the sewing process and flag problems before they get out of hand.

-

Real-Time Alerts: You’ll know right away if something goes sideways.

-

Automatic Stop: The machine halts to prevent wasted materials and keep quality up.

-

Detailed Reports: Get breakdowns of what went wrong, so you can tweak things next time.

Customizability Options

Customizability is definitely on the rise. Many machines let you adjust settings to match your specific needs.

-

Adjustable Stitch Length and Width: Tweak these for different bag types without much fuss.

-

Programming for Different Materials: Set up profiles for various fabrics—makes life easier.

-

User-Created Patterns: Save your go-to sewing patterns for repeat jobs.

These options make it way easier to adapt and keep your line running smoothly, no matter what’s on the schedule.

Role in Air Filtration Solutions

Automatic filter bag sewing machines are key to making high-quality filter bags. They’re a big part of effective air filtration systems and play a role in protecting the environment.

Enhancing Filter Bag Quality

With automatic machines, you get precise stitching and stronger seams. That means bags last longer and resist leaks, even with heavy airflow.

Advanced tech keeps tension and stitch patterns consistent, so every bag fits its filtering job. Consistent quality means better dust and contaminant trapping—cleaner air all around.

Contribution to Environmental Protection

Air filtration cuts down on pollution, and good filter bags are at the heart of that. Automatic sewing machines help make bags that filter better, which means fewer emissions.

Longer-lasting bags mean less waste and lower costs, both for production and disposal. That’s good news for the environment—and your bottom line.

Trends and Future Developments

The demand for effective air filtration just keeps climbing. As industries get more serious about environmental responsibility, automatic sewing machines are going through some interesting changes.

They’re now able to handle a bigger variety of materials, including high-tech stuff like meta-aramid and PPS felt. These fabrics really push filtration performance up a notch.

We’re seeing programmable features pop up that make production even more efficient. Machines are getting easier to use, too—operators can tweak settings for different filter bags without much fuss.